Reducing costs in sludge dewatering with filter belts:

Tips and best practices

Reducing costs in sludge dewatering with filter belts: tips and best practices

Reducing costs in sludge dewatering with filter belts: Tips and best practices

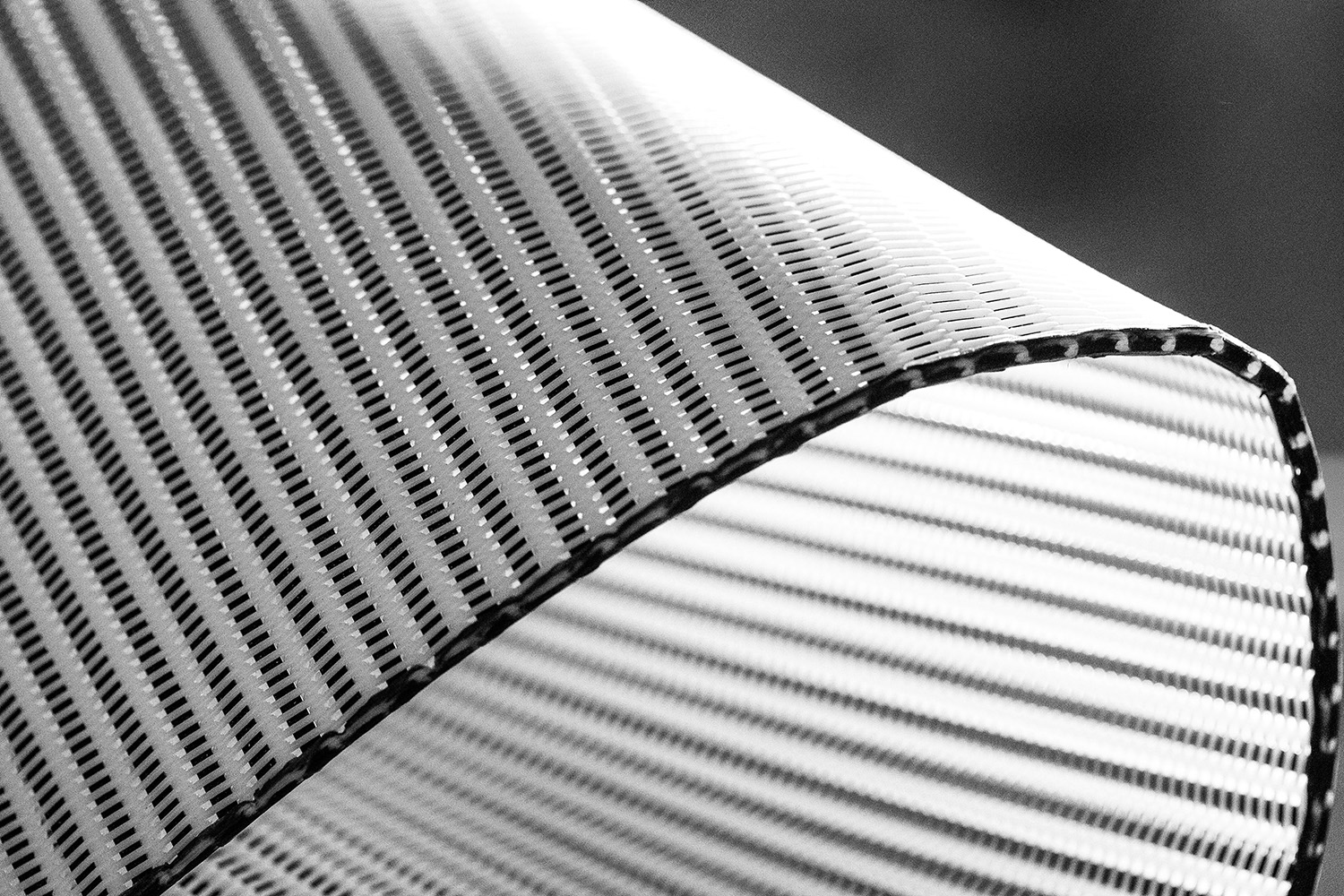

Sludge dewatering with filter belts is a critical process in the wastewater treatment industry, but it can also be costly. Fortunately, there are several ways to reduce costs while still achieving maximum efficiency and effectiveness. In this article, we will explore some tips and best practices for reducing costs in sludge dewatering with filter belts.

1. Select the right belt

The selection of the right filter belt is critical to achieving maximum efficiency and cost reduction in sludge dewatering. A belt that is not suitable for the application can lead to higher energy consumption, reduced solids capture rates, and increased maintenance costs. By selecting the right belt for the application, you can reduce these costs and achieve maximum efficiency.

2. Optimize belt maintenance

Proper belt maintenance is essential to ensuring maximum efficiency and reducing costs. Regular cleaning, inspection, and replacement of worn or damaged components can prevent downtime and reduce the risk of belt failure. Implementing a preventative maintenance program can help identify issues before they become major problems, reducing repair and replacement costs.

3. Monitor energy consumption

Energy consumption is one of the significant costs associated with sludge dewatering. By monitoring energy consumption and identifying areas of high consumption, you can implement energy-saving measures, such as optimizing the process flow or reducing the amount of sludge processed. This can lead to significant cost savings over time.

4. Implement process optimization

Optimizing the sludge dewatering process can help reduce costs by improving efficiency and reducing the amount of sludge produced. Implementing process optimization measures such as proper sludge conditioning, optimizing chemical usage, and improving sludge dewatering equipment can lead to higher solids capture rates and lower energy consumption.

5. Reduce waste disposal costs

Waste disposal costs can be a significant expense in sludge dewatering. By reducing the amount of sludge produced and increasing solids capture rates, you can reduce the amount of waste that needs to be disposed of, leading to lower costs. Additionally, exploring alternative waste disposal options, such as land application, can also help reduce costs.

Conclusion

Reducing costs in sludge dewatering with filter belts requires a comprehensive approach that includes selecting the right belt, optimizing maintenance, monitoring energy consumption, implementing process optimization, and reducing waste disposal costs. By following these tips and best practices, you can achieve maximum efficiency, reduce costs, and ensure environmental sustainability. With the right approach, sludge dewatering with filter belts can be a cost-effective and efficient process that contributes to a healthier environment and community.

Sludge dewatering with filter belts

Our portfolio of filter belts offers a wide range of solutions for various sludge dewatering applications. We understand that each industry has unique requirements when it comes to sludge dewatering, and our filter belts are designed to meet these specific needs. Whether you need a belt that can handle high-temperature drying or one that is resistant to abrasive sludge, our portfolio has you covered.

We work closely with our clients to understand their specific requirements and develop customized solutions that offer maximum efficiency and effectiveness. Our commitment to quality and innovation ensures that our filter belts are at the forefront of the industry, delivering exceptional results and helping our clients achieve their sludge dewatering goals.

Arrange a call

Please feel free to send me a message. Either directly by

e-mail or add me to your network on LinkedIn and contact me there. I look forward to meeting you and talking to you about solving your problems.

Address

R+F FilterElements GmbH

Wollenweberstraße 25

31134 Hildesheim

Germany