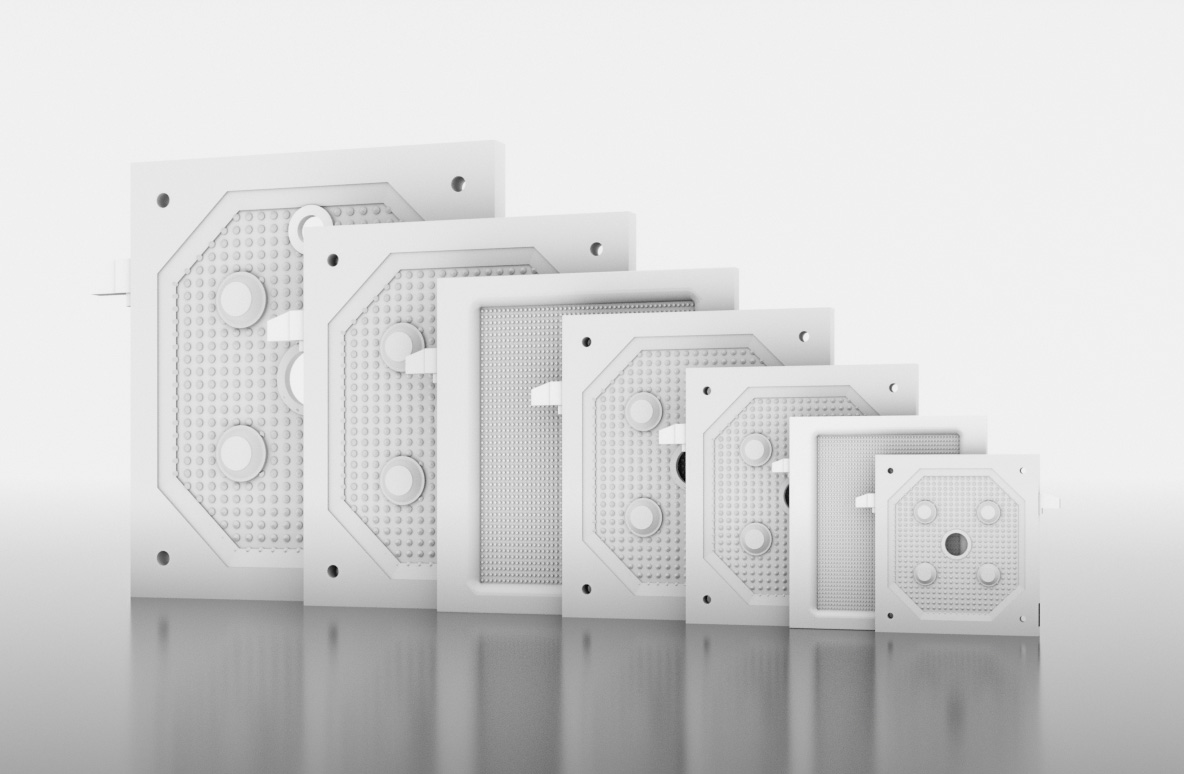

Filter plates for chamber filter presses

Maximize your operations with high-performance filter plates

Efficient and reliable filter plates are the backbone of any successful chamber filter press operation.

Maximizing efficiency and performance with high-quality filter plates for chamber filter presses

Filter plates are an essential component of filter presses, used in solid-liquid separation processes from various industrial and municipal wastewater treatment applications. These plates can be made of different materials, including polypropylene, cast iron, stainless steel, and others, and are available in different sizes and designs to suit specific requirements. By selecting the right filter plate material and design, the filter press can achieve optimal dewatering efficiency, resulting in reduced disposal costs, improved sustainability, and easier handling and transportation of dewatered filter cakes.

Have a look at our portfolio of filter plates for chamber filter presses

Our portfolio of filter plates for chamber filter presses provides reliable and efficient solutions for solid-liquid separation in a variety of industrial and municipal wastewater treatment applications. Filter plates are a crucial component of chamber filter presses, and our high-quality plates are designed to ensure optimal performance and maximum cake dryness. Available in a range of materials, sizes, and designs, our filter plates are customizable to meet the unique needs of your operation. Whether you’re looking to improve dewatering efficiency, reduce disposal costs, or increase sustainability, our filter plates for chamber filter presses have a solution for you.

Standard filter plates

Our standard filter plates made from white polypropylene are a reliable and cost-effective solution for solid/liquid seperation in various applications. With their excellent chemical resistance our filter plates ensure optimal performance and maximum efficiency of the filter press, resulting in drier and easier filter cakes.

CGR - Caulked gasket recessed filter plates

Our CGR (Caulked Gasket Recessed) filter plates provide a superior sealing solution for chamber filter presses, ensuring no leakage and maximum dewatering efficiency. With their specially designed gasket groove and caulking system, our CGR filter plates provide a tight seal, resulting in drier and easier to handle filter cakes, reducing disposal costs, improving sustainability and ensure optimal performance.

High pressure filter plates

Our high pressure filter plates with a maximum pressure of 30 bar are designed to provide reliable and efficient solutions for high-pressure dewatering applications. With their robust construction our filter plates ensure optimal performance and maximum cake dryness even in the most demanding environments.

Roundplate filter plates

Our round plate filter plates are an efficient and cost-effective solution for solid-liquid seperation in round filter presses. With their simple design and ease of use, our filter plates provide reliable performance and high cake dryness, resulting in reduced disposal costs and improved sustainability. Available in a range of sizes and materials, our round plate filter plates are customizable to meet the unique needs of your operation.

High temperature filter plates

Our high temperature filter plates with a maximum operating temperature of 120°C are designed to provide reliable and efficient solutions for high-temperature dewatering applications. With their excellent heat resistance, our filter plates ensure optimal performance and maximum cake dryness.

Phosphor bronze roundplate filter plates

Our phosphor bronze round plate filter plates provide a reliable and durable solution for solid-liquid separation in round filter presses. With their excellent corrosion and wear resistance, our filter plates ensure optimal performance and maximum cake dryness even in the most demanding environments. Our phosphor bronze round plate filter plates are a cost-effective and sustainable solution for your solid-liquid separation needs.

Arrange a call

Feel free to write me a message. Either directly by

e-mail or add me to your network on LinkedIn and contact me there. I look forward to meeting you and talking to you about solving your problems.

Address

R+F FilterElements GmbH

Wollenweberstraße 25

31134 Hildesheim

Germany