improved lubricant performance and reduced oil degradation

Improved lubricant performance and reduced oil degradation

How to improve lubricant performance and reduce oil degradation

Lubricants play a critical role in maintaining the health and performance of rotating equipment. However, the presence of contaminants in the lubricant system can lead to reduced performance and increased oil degradation. This is where high efficient lube oil filtration comes in.

Proper lube oil filtration helps to eliminate contaminants from the lubricant system, preserving the health of the oil and ensuring that it performs its intended function effectively. When the lubricant is free from contaminants, it remains cleaner, reducing oil degradation and improving its ability to perform its intended function. This results in improved lubricant performance and extended oil life, reducing the frequency of oil changes and associated costs.

In addition to reducing oil degradation, high efficient lube oil filtration also helps to improve the efficiency of the equipment. Contaminants in the lubricant system can cause increased wear and tear on the equipment components, leading to reduced efficiency and increased maintenance requirements. By eliminating these contaminants, the risk of wear and tear is reduced, and equipment efficiency is improved.

It’s important to understand that lube oil filtration is not a one-time event but an ongoing process. Regular monitoring and maintenance of the lube oil filtration system is critical to ensure that it operates efficiently and provides the desired benefits. This includes monitoring the performance of the filter, changing the filter element when required, and checking the lubricant cleanliness level to ensure that contaminants are being effectively removed.

In conclusion, the importance of high efficient lube oil filtration cannot be overstated when it comes to maintaining the health and performance of rotating equipment. By ensuring the lubricant system remains clean and contaminant-free, lubricant performance is improved, oil degradation is reduced, and equipment efficiency is enhanced. Regular monitoring and maintenance of the lube oil filtration system is a crucial aspect of ensuring that equipment operates at optimal performance and that these benefits are realized.

High efficiency lube oil filtration innovation

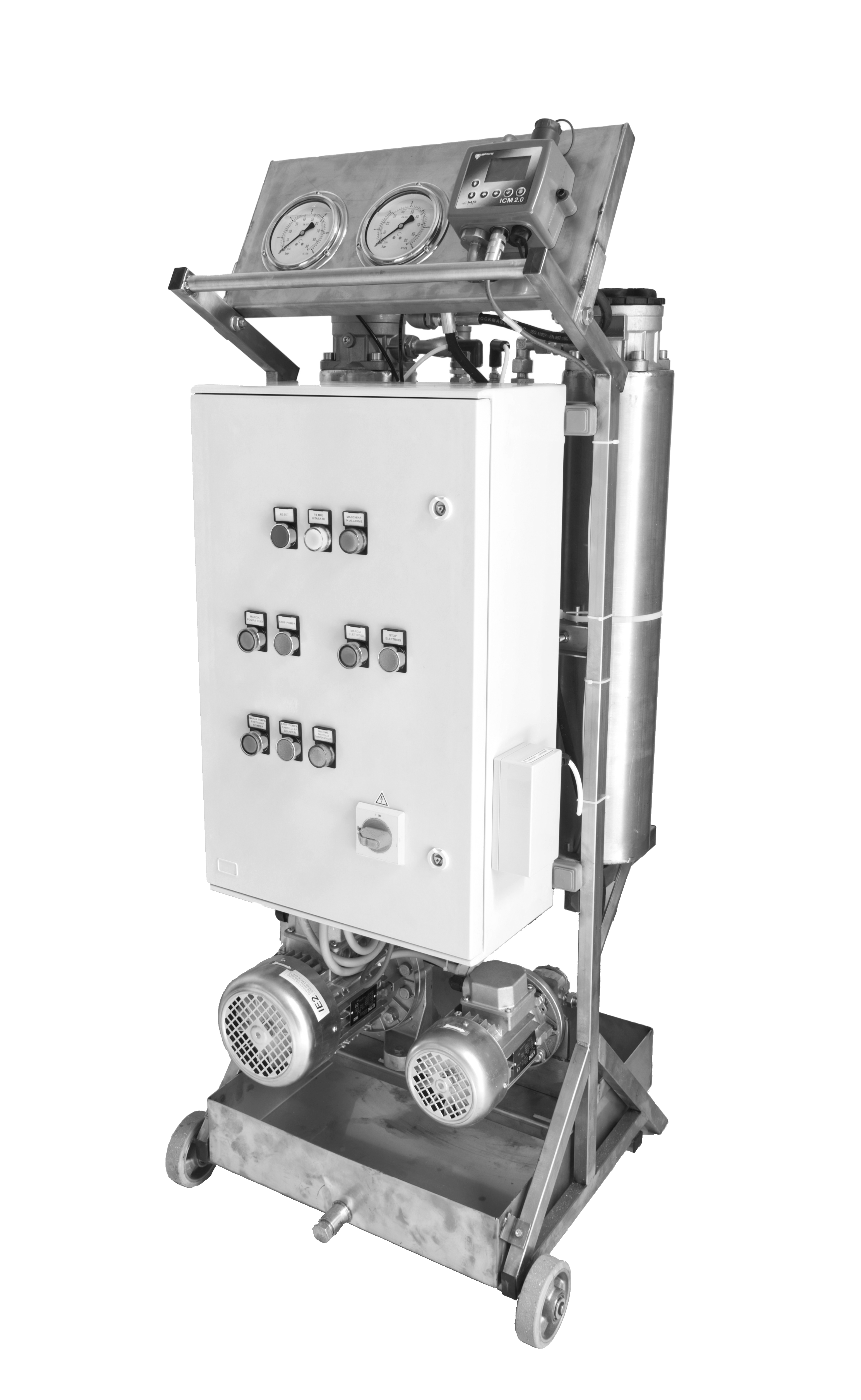

Introducing the High Efficient Pseudo-Ion Lube Oil Filter, designed to provide superior filtration performance for your lubrication system. With its ability to filter particles down to 0.1 microns, this filter offers exceptional protection against wear and tear on your equipment, extending the life of your machinery. This filter is designed for use in a wide range of applications, from heavy duty industrial machinery to automotive and transportation systems.

The high efficient lube oil filter uses advanced filtration media to trap even the smallest impurities and contaminants, ensuring that your lube oil remains free of harmful particles. This helps to prevent damage to your equipment and maintain optimal performance, even under the most challenging conditions. Whether you’re looking to protect your investment in high-value machinery or simply ensure the longevity and reliability of your equipment, this high efficient lube oil filter is an essential component in your lubrication system.

So why wait? Invest in the High Efficient Lube Oil Filter today and enjoy the peace of mind that comes with knowing that your equipment is protected by the best.

Arrange a call

Please feel free to send me a message. Either directly by

e-mail or add me to your network on LinkedIn and contact me there. I look forward to meeting you and talking to you about solving your problems.

Address

R+F FilterElements GmbH

Wollenweberstraße 25

31134 Hildesheim

Germany